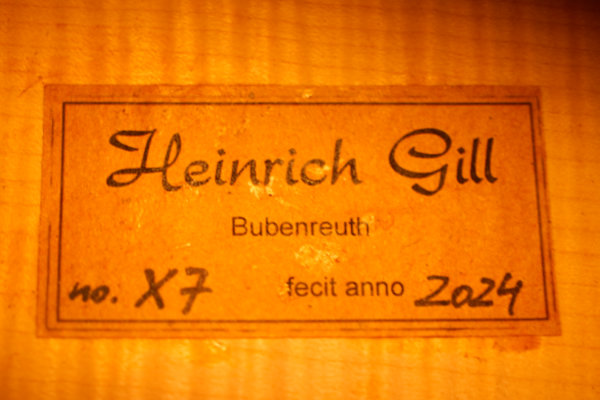

Heinrich Gill Geigenbaumeister, Bubenreuth Germany

Heinrich Gill X7 Carcassi

This is the X7 Carcassi model cello from the top line of the Gill workshop, specially made for the American market by master luthier Bernd Dimbath.

The cello is finished in a amber-brown oil-based lacquer.

The back is made of well-flamed European maple wood. The sides are also made of maple and beautifully flamed. The top is European spruce with a nice pattern of evenly spaced annual rings.

For this cello, the Gill company selected their top quality matched pieces.

The dimensions of this (4/4) cello:

- upper width 35 cm

- narrowest width 25 cm

- bottom width 43 cm

- body height (to the heel) 73 cm

- the scale is 69 cm (keel to bridge)

- the cello fits in an ordinary cello case.

During the creation process of this cello, the natural acoustic properties of the instrument components are continuously measured and monitored. Components are then perfectly matched and harmonized together according to the carefully determined natural acoustical characteristics of the wood in order to maximize the instrument’s potential. This is what Gill is famous for.

The current setup consists of:

- Belgian cello bridge

- Teller ebony tailpiece with integrated finetuners

- Teller Hill-model ebony tunng pegs with fitted rings of boxwood

- ebony fingerboard

- ULSA (USA) endpin

String setup

The cello is strung up with Larsen Soloist on A and D and Thomastik Spirocore Tungsten strings on the G and the C. The final setup for this instrument can be chosen by the buyer, in the sound optimisation proces where the buyer will be supported by cellist and cello-string-specialist Mirjam Daalmans from the Gallery.

About the Gill workshop

The making of fine instruments begins with careful and experienced selection of the tonewood. At Gill, they combine scientific measurements with the trained and expert eye – the wood selection process is second to none!

As a small manufacturing workshop Gill buy their raw materials mainly from local tonewood sawmills, but also from dealers who quite often have very good wood available. From Gills point of view, the origin is not so important, the acoustical quality matters!

They have set up a reliable measurement system to evaluate the most important characters of tonewood. Their raw materials are selected with the support of a scientifically based qualification structure.

In search for the “ultimate sound”, the process begins with the selection of tonewood from their extensive inventory of European aged timbers. They quantitatively measure the quality of the wood under different physical aspects in order to arrive at an objective and clear determination of the qualities of the woods used. During the making process, the natural acoustic properties of the instrument components are continuously measured and monitored.

The result is a unique development of each piece of wood. Components are then perfectly matched and harmonized together – according to the carefully determined natural acoustical characteristics of the wood – to maximize the instrument’s potential. Working in small batches of 6-8 instruments at a time, all tonewoods are hand selected, and individually graduated by Bernd Dimbath.

Each component within the batch is meticulously measured to evaluate its inherent acoustical characteristics and then sonically fine-tuned. Components are then perfectly matched together according to the harmonized acoustical characteristics. Components are then perfectly matched together according to the harmonized acoustical characteristics.

The wood, used in this X-7 series (the top of Gills range) is of ultra-high quality. Only the best in stock is used.

About the Heinrich Gill brand history

Since 1952 Gill is creatively connected with the Violin Making in Bubenreuth (Bavaria region, Germany). The company was found in Bubenreuth in 1952 by Heinrich Gill. His family has already been involved in the music business for 5 generations.

Because of the existing international connections the business grew rapidly, musical Instruments and accessories were exported to all continents.

In 1990 the company was bought by Bernd Dimbath, Violin Maker who visited the Mittenwald School of Violin Making during his apprecticeship.

From now on the main focus was on bowed instruments only and the workshop became the major goal. Until today the combination of the 300 years old violin making tradition with modern and innovative technology has proven to be the key for the progress and continued success of the workshop.

With a huge amount of dedication Bernd Dimbath has developed a completely new approach to the making process. Numerous scientifically based measurement methods are involved today in the workshop, making HEINRICH GILL the only manufacturer worldwide who can guarantee the acoustical performance of each single instrument that leaves the workshop!

price available upon request